Server algorithms were optimized to find a proper performance in data handling. In practice new on-PLAN is used with more than 3000 operations in a certain plan. The first download takes less than 1 minute and this response time can be considered general.

On the client side several functions can be switch on-off to avoid unnecessary calculations such as FLASH MRP by items. Response time is cut down dramatically.

on-PLAN is available for SAP, Dynamics AX, NAV via connectors. Work orders are downloaded from the ERP, and the scheduled plan uploaded by the standardized interface.

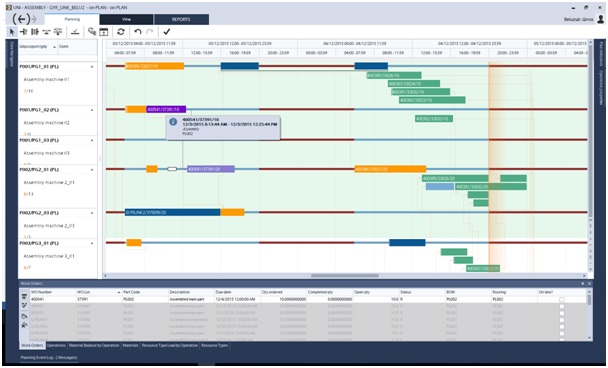

During the background process user gets back the cursor and the scheduling can be continued. The background process is signed by color codes in the operations not released yet.

Any activities on the planning board can be down separately from the algorithms. on-PLAN platform and the User interact real time.

New type of date is launched to keep required date of customers.

Required date default is equal the work order due date. Work order late status is based on the required date on the planning board. The original due date is modified by on-PLAN to the scheduled finish date. This information is necessary for the consequent MRP running. Required date is not modified by on-PLAN to preserve the original date of demand.

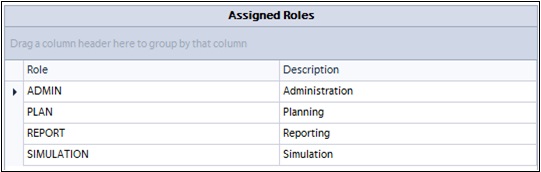

This SIMULATION type of user can modify the plan with the following limits:

- User can open and copy his/her own plans.

- Plan can be modified, but the release and upload to QAD is restricted.

Simulation user can be a sales person who runs several scenarios to find the availability to promise date of a new order or a project leader to schedule a new project. This type of user can also help to schedule a sample product production or create a “what if plan” with possible new resources.

on-PLAN follows the positioning of selected operations during the manual movement and corrects the position based on the current circumstances of the board. User face up the consequence of the new position of the operation before it is placed. Earlier version could response after placing an operation, now calculation happens real time.

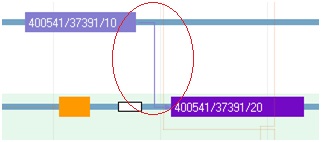

Link conflict is prohibited, the operation movement stops on the link borders whether the linked operation is on the board. The linked operations in BIN will be pushed. Moving backwards: linked operations try to reach their original position.

Operations cannot be moved between two machine alternate periods, in case of conflict with more periods: operation tries to fit in to the nearest location possible (regarding to circumstances and throughput time).

The length of the process changes real time according to the alternate routing defined when moving to an alternate machine.

While moving the cursor icons indicate an invalid position.

Inscriptions of the planning board operations can be parameterized so that the relevant data of operations can be displayed depending on the industrial environment requirements.

For example automotive prefers work order lot and operation, pharmaceuticals choose batch number meanwhile item number or description can be relevant in food industry.

Selection driven Sort order on the parallel BIN operations. Any operations can be made visible even when it is not displayed properly because of the huge amount of operations in the bin. New operations on the board can be scheduled step by step, while relevant operations are on the top.

Tooltip on the consolidated operations, downtime, changeover time.

Several industries require strict order of operation. For example in food industry the non-allergen products must be produced earlier than products containing allergen ingredients. Cleaning, tool change, other changeover activities can be avoided with the right order of the operations. This function guarantees to keep the predefined orders of the operations during the optimization process.

Pharmaceutical industry creates a strict work order structure for a certain product called batch. Meanwhile the batch structure is built the links can be created in a special table which contains the preceding work orders for an operation. The generated links are downloaded to on-PLAN and provide to keep the technological order between work orders.

-

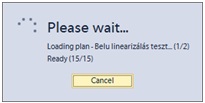

Interrupted processes on the UI: plan opening; refreshment, upgrade, plan distribution, down time add, down time delete, optimization. The process can be followed on a pop-up window, and that can be interrupted with a CANCEL button.

Interrupted processes on the UI: plan opening; refreshment, upgrade, plan distribution, down time add, down time delete, optimization. The process can be followed on a pop-up window, and that can be interrupted with a CANCEL button.

- Manual movement is synchronized with the server in the background. Color codes sign the synchronization. User gets back the cursor, planning process can be continued. The server examines the new position. The server releases the new position or sends an error message and makes a rollback of the last movements.

- Flash MRP runs in the background, the interactive info grid is refreshed by the algorithm.

- The order of work centers / machines can be defined.

- New Priority levels. The work order number is the last priority level. That level is evaluated after the higher priority levels, like item priority, Due Date, technical priority, lead time.

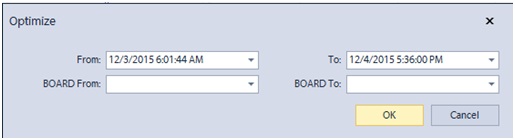

- Interval Optimization: Interval filter is added to optimization function. The algorithm works on the filtered operations only. The plan can be divided into small planning periods and the completed periods can be frozen by the interval limits. The interval filter defaults are empty and the optimization runs in the original way in this case.

- Zoom machines to selection: Work centers and machines are filtered by selected operations. The function hides the currently irrelevant work centers so that the scheduler can focus on the essential planning area.

- Flash MRP can be switch on – off by items. Unnecessary calculations can be avoided and the performance can be optimized by that parameter.

- The released plan is copied to special plan named LIVE. The LIVE plan cannot be modified, it contains all the details of the actual plan.

- Live plan contains the flash MRP details in the release status.

- LIVE plan can be copied. The copy can be modified.

- Performance improvement on client and server functions.

- Server algorithms were optimized to find a proper performance in data handling. In practice new on-PLAN is used with more than 3000 operations in a certain plan. The first download takes less than 1 minute and this response time can be considered general.

- On the client side several functions can be switch on-off to avoid unnecessary calculations such as FLASH MRP by items. Bug fixing cuts down response time dramatically.

-

Separated UI from background.

- During the background process user gets back the cursor and the scheduling can be continued. The background process is signed by color codes in the operations not released yet.

- Required date is separated from due date – effective MRP and on-PLAN principle: required date default is equal the work order due date. Work order late status is based on the required date on the planning board. The original due date is modified by on-PLAN to the scheduled finish date. This information is necessary for the consequent MRP running. Required date is not modified by on-PLAN to preserve the original date of demand.

-

NEW User Type for Scenario analysis. This SIMULATION type of user can modify the plan with the following limits:

- User can open and copy his/her own plans.

- Plan can be modified, but the release and upload to QAD is restricted.

- Simulation user can be a sales person who runs several scenarios to find the availability to promise date of a new order or a project leader to schedule a new project. This type of user can also help to schedule a sample product production or create a “what if plan” with possible new resources.

-

on-the-fly positioning in manual movement

- on-PLAN follows the positioning of selected operations during the manual movement and corrects the position based on the current circumstances of the board.

- Link conflict is prohibited, the operation movement stops on the link borders whether the linked operation is on the board. The linked operations in BIN will be pushed. Moving backwards: linked operations try to reach their original position.

- Operations cannot be moved between two machine alternate periods, in case of conflict with more periods: operation tries to fit in to the nearest location possible (regarding to circumstances and throughput time).

- The length of the process changes real time according to the alternate routing defined when moving to an alternate machine.

- Moving operations to invalid position is not allowed by manual movement. This modification highly reduces the number of incorrect movements.

- While moving the cursor icons indicate an invalid position.

- Inscriptions of the planning board operations can be parameterized so that the relevant data of operations can be displayed depending on the industrial environment requirements

- Selection driven Sort order on the parallel BIN operations.

- Any operations can be made visible even when it is not displayed properly because of the huge amount of operations in the bin.

- Tooltip on the consolidated operations, downtime, changeover time.

- Strict priority control on technological level. This function guarantees to keep the predefined orders of the operations during the optimization process.

- Auto links based on the BOM structure. Links can be created in a special table which contains the preceding work orders for an operation. The generated links are downloaded to on-PLAN and provide to keep the technological order between work orders.

Auto Scheduled Changeover activities

Predefined view selection on time horizon from 1 year to 1 minute

Automatic job share on alternate machines

(horizontal or vertical sharing algorithm)

Color codes for material shortages, priority, project

Operational groups

Parallel activities on different machines

Work Order Split

Operation split

Temporary capacity variance

UI navigation upgrade (zoom, hide, hot keys)

Extended report package for sales, production, purchasing

Other ERP connectors